Are you struggling with how to calculate percentage elongation? Do you find yourself lost when it comes to understanding the formula or trying to interpret the results? If so, don’t worry, as you’re not alone. In this article, we’ll break down the process for you step-by-step and provide helpful tips along the way.

Figuring out how to calculate percentage elongation can be a tedious process. Many people find it overwhelming to understand the formula or how to interpret the results. Luckily, there are simple steps one can follow to make the process easier.

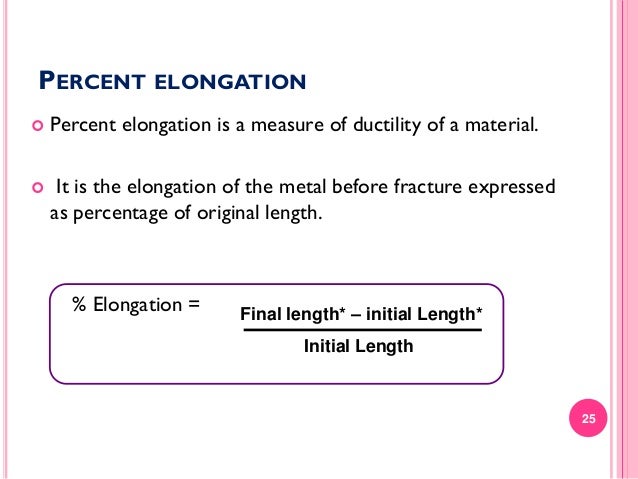

The formula for calculating percentage elongation is relatively simple. First, subtract the original length of the material from its final length. Then, divide that number by the original length and multiply the result by 100. This will give you the percentage elongation of the material. For example, if the original length of the material was 10cm and its final length was 13cm, the percentage elongation would be calculated as follows: (13 – 10) / 10 x 100 = 30%.

In summary, to calculate percentage elongation, one needs to follow a straightforward formula. Subtract the original length of the material from its final length, divide that number by the original length, and then multiply the result by 100. By using this method, one can quickly and easily calculate the percentage elongation of any material.

How to Calculate Percentage Elongation: Explained

When I was first learning how to calculate percentage elongation, I found it incredibly confusing. However, after some research and practice, I discovered a few tricks to make the process easier.

First and foremost, it’s crucial to ensure that all measurements are precise. Any deviation can significantly impact the final result. Additionally, it’s essential to use the correct units of measure in order to ensure accuracy.

Another key tip when figuring out how to calculate percentage elongation is to look for patterns in your results. Over time, you may notice that certain materials behave differently or produce consistent results. This information can help you anticipate future results and make adjustments accordingly.

The Importance of Percentage Elongation

Percentage elongation is a critical factor in various fields, including engineering, construction, and materials science. Understanding how to calculate percentage elongation can help a professional make informed decisions about which materials to use and how to use them effectively.

The Relationship between Tensile Stress and Percentage Elongation

One significant factor to consider when calculating percentage elongation is the material’s tensile stress. Tensile stress refers to the amount of force required to pull a material apart. The relationship between tensile stress and percentage elongation is proportional – the higher the tensile stress, the lower the percentage elongation.

The Impact of Temperature on Percentage Elongation

When calculating percentage elongation, it’s essential to consider the impact of temperature on the material. As temperature increases, so does the material’s ductility. This means that the material becomes more malleable and, as a result, more susceptible to elongation.

Common Questions about How to Calculate Percentage Elongation

Q: Is percentage elongation the same as strain?

A: No, while both are measures of how much a material has stretched, strain measures the deformation per unit length, while percentage elongation measures the material’s extension as a percentage of its original length.

Q: Why is percentage elongation important?

A: Percentage elongation is important because it provides insights into how a material will behave in different scenarios. This information can shape design decisions and help prevent equipment failure.

Q: How can I improve my percentage elongation results?

A: To improve your results, make sure that all measurements are precise, use the correct units of measure, and be consistent in how you conduct tests.

Q: How does temperature affect percentage elongation?

A: Temperature can impact percentage elongation in that higher temperatures can increase a material’s ductility, making it more susceptible to elongation.

Conclusion of How to Calculate Percentage Elongation

In conclusion, understanding how to calculate percentage elongation is crucial in various fields, including engineering, construction, and materials science. By following a simple formula and considering factors such as tensile stress and temperature, professionals can gain valuable insights into how a material behaves and use this information to make informed design decisions. So whether you’re a student or a professional, take the time to master the art of calculating percentage elongation, and unlock a new level of expertise in your field.

Gallery

How To Calculate Ductility | Sciencing

Photo Credit by: bing.com / calculate ductility elongation percent equation material length gauge lf following using

Phy351 Ch 6

Photo Credit by: bing.com / elongation ductility calculation

How To Calculate Percent Elongation – Easy To Calculate

Photo Credit by: bing.com / elongation percent calculate equation

How To Calculate Uniform Elongation – Calculatorf

Photo Credit by: bing.com /

Total Elongation – AHSS Guidelines

Photo Credit by: bing.com / tensile elongation curve fracture deformation forming ahssinsights