The ability to calculate percentage tolerance is an essential skill that many professionals and industries rely on. Whether you work in manufacturing, quality control, or engineering, knowing how to calculate percentage tolerance is crucial for ensuring products meet quality standards and specifications. In this post, we’ll provide an in-depth guide on how to calculate percentage tolerance and its importance in various industries.

When it comes to calculating percentage tolerance, there are several pain points that professionals may encounter. For example, measuring the accuracy of instruments or gauging and meeting customer specifications can be challenging without proper knowledge of percentage tolerance. Additionally, failing to meet these standards can lead to costly rework, customer dissatisfaction, or even potential legal consequences.

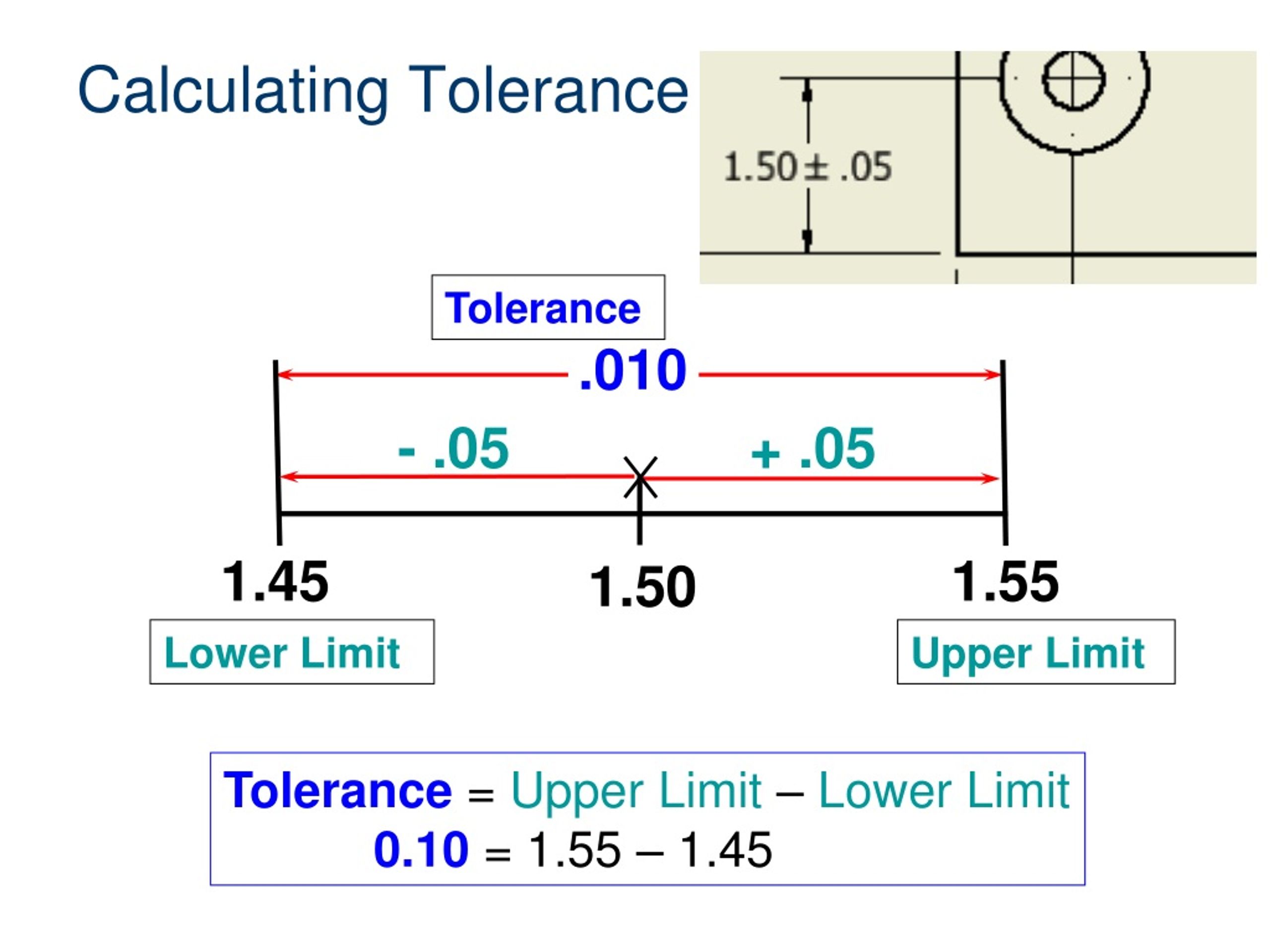

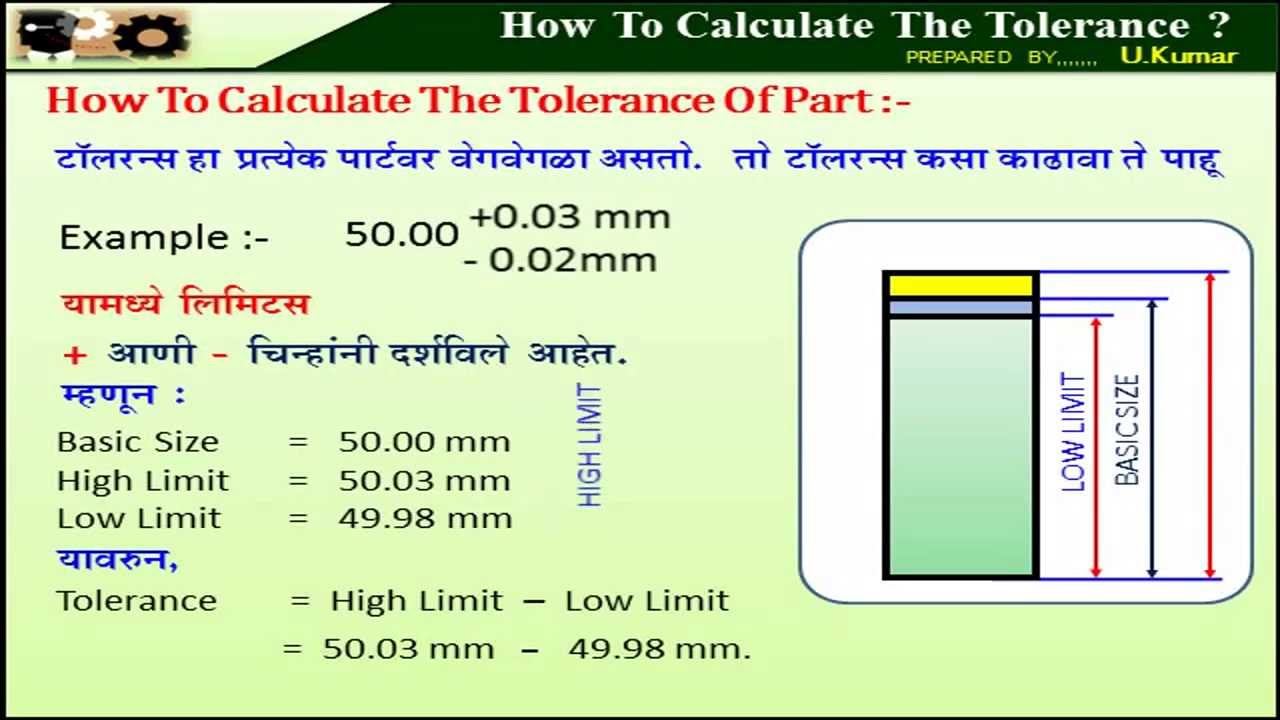

To calculate percentage tolerance, you need to understand the relationship between the actual dimension of a part or product and the allowed tolerance range. The percentage tolerance is then calculated by determining the allowable deviation from the standard and expressing that deviation as a percentage of the nominal value.

In summary, to calculate percentage tolerance, you need to follow a few simple steps. First, determine the nominal value or target value for the part or product you are measuring. Next, determine the acceptable range of deviations from the nominal value. Finally, calculate the percentage tolerance by dividing the acceptable range by the nominal value and multiplying by 100.

Understanding the significance of Percentage Tolerance

While calculating percentage tolerance may seem straightforward, it’s essential to understand its significance. In my experience working in quality control, I’ve seen many instances where inaccurate measurements resulted from not properly understanding how to calculate percentage tolerance. For example, a client once rejected a critical component in our product because it failed to fall within the required tolerance range, costing us both time and money. You can avoid such situations by understanding how to calculate percentage tolerance.

Factors Affecting Percentage Tolerance Calculation

Several factors can affect the accuracy of percentage tolerance calculations. These factors include the quality of the measuring instrument, the skill level of the operator, environmental factors such as temperature and humidity, and the materials used in the production process. By considering and accounting for these factors, you can ensure accurate and precise percentage tolerance calculations.

Measuring the Accuracy of an Instrument

To ensure the accuracy of your measuring instruments, you should calibrate them regularly against a traceable and certified standard. Calibration will help you to determine the degree of accuracy and adjust the instrument’s readings accordingly. Without calibration, the possibility of measurement errors and inaccurate percentage tolerance calculations is significantly high.

Importance of Materials in Percentage Tolerance Calculation

The choice of materials and their properties play a critical role in calculating percentage tolerance. The properties of the materials used will affect the dimensional accuracy of the part being produced. Understanding the properties of the material is important when selecting the tolerance range and making calculations that will result in the intended specifications.

Common Mistakes in Calculating Percentage Tolerance

While calculating percentage tolerance may seem simple, there are some common mistakes to avoid. One common mistake is assuming the same percentage tolerance for all parts or products. In reality, each part may have different specifications and therefore require different tolerance ranges. Another mistake is miscalculating the percentage tolerance by forgetting to convert the tolerance values to the same units as the nominal value.

Frequently Asked Questions

1) What is the acceptable percentage tolerance for product quality assurance?

The acceptable percentage tolerance for product quality assurance varies from industry to industry and depends on the specific product’s requirements. In some industries, a percentage tolerance of +/- 0.1% may be acceptable, while in other industries, a range of +/- 10% may be acceptable.

2) How do you calculate percentage tolerance in excel?

To calculate percentage tolerance in Excel, you need to use a basic formula that divides the allowable tolerance range by the nominal value and multiplies it by 100. For example, if the nominal value is 10 and the tolerance range is +/- 0.5, you would use the formula = ((0.5*2)/10)*100 to get a percentage tolerance of 10%.

3) What is the difference between percentage tolerance and percentage error?

Percentage tolerance and percentage error are two related but different concepts. Percentage error is the difference between the actual and expected values, expressed as a percentage of the expected value. Percentage tolerance, on the other hand, is the allowable range of deviation from the nominal value expressed as a percentage of the nominal value.

4) How often should you calibrate measuring instruments used for percentage tolerance calculation?

The frequency of calibration depends on the instrument’s use frequency and industry standards, but as a general rule, measuring instruments should be calibrated at least once a year. However, if the instrument is used frequently or in harsh environments, it may be necessary to calibrate it more frequently.

Conclusion of how to calculate percentage tolerance

Calculating percentage tolerance plays a crucial role in ensuring product quality and meeting customer specifications. By following the steps outlined in this post, you can accurately calculate percentage tolerance and avoid costly mistakes. Remember to consider factors such as calibrating your measuring instruments, accounting for environmental factors, the choice of materials, and avoiding common mistakes when calculating percentage tolerance. This will ensure that your products meet quality standards and that you maintain customer satisfaction.

Gallery

PPT – Tolerances PowerPoint Presentation, Free Download – ID:481230

Photo Credit by: bing.com / tolerance tolerances calculating limits

17. How To Calculate The Tolerance Of Part ? – YouTube

Photo Credit by: bing.com / tolerance calculate

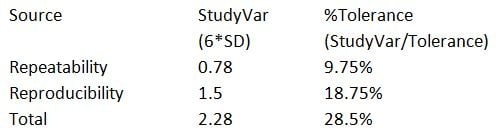

Evaluating A Gage Study With One Part

Photo Credit by: bing.com / tolerance multiplied course results were

MSA Measurement System Analysis

Photo Credit by: bing.com / msa gage tolerance error measurement analysis system sigma study percentage variable six material divide formula process calculating production convert

Class Of Check Weights | Determining The Right Tolerance For Your Balance

Photo Credit by: bing.com / tolerance determine readability